POWDER BED ADDITIVE MANUFACTURING OF TRANSITION METAL DICHALCOGENIDES-BASED COMPOSITES FOR ELECTROCHEMICAL SYSTEMS (BEAM-TMD)

The advancement of 2D crystallographic structures of transition metal dichalcogenides (TMDs) has received great attention in recent years, owing to their outstanding properties such as adequately big surface area and strength. Compared to other 2D materials, TMDs have high-temperature stability, direct bandgap, and hence tunable electrical and thermal conductivity. There has been limited knowledge of systematically synthesizing novel sets of TMDs-based composites in emerging electrochemical systems. The powder bed fusion (PBF) process, as a well-known additive manufacturing method, can successfully overcome the demerits of current TMDs processing approaches and advance the scalability of dual-functional electroactive components.

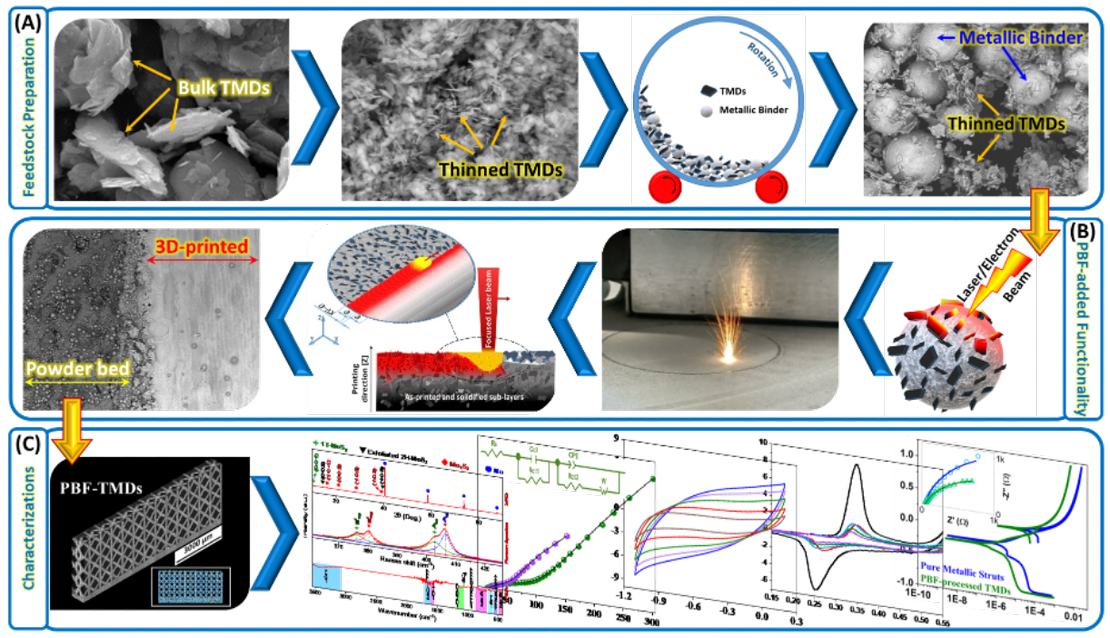

In this project, we will address the following fundamental question: How is PBF exploited as a scalable processing technique to achieve TMDs-based metal matrix composites with tuned chemical-, physical-, crystallographic, and electrochemical properties? To this goal we will: (a) select and synthesize a set of promising 2D TMDs-mixed metal matrix feedstock to be utilized for powder bed AM; (b) develop and optimize the PBF process parameters, which drastically affects the performance of the selected TMDs-incorporated composite powder; (c) develop a test sample matrix and test plan (electrochemical, microstructural, and thermophysical). The 3D-printed structures with precise micro-/nanostructure and tailored surface chemistry simultaneously perform as integrated electroactive phases and current collectors in advanced electrochemical-based technologies

In collaboration with The KTH Royal Institute of Technology, we will establish a paradigm shift in the synthesis of new materials and dual-functional components of electrochemical systems.