ADVANCING SPACE APPLICATIONS THROUGH 3D VOXEL-BASED MULTI-MATERIAL LASER POWDER BED FUSION (SPACEFUSE)

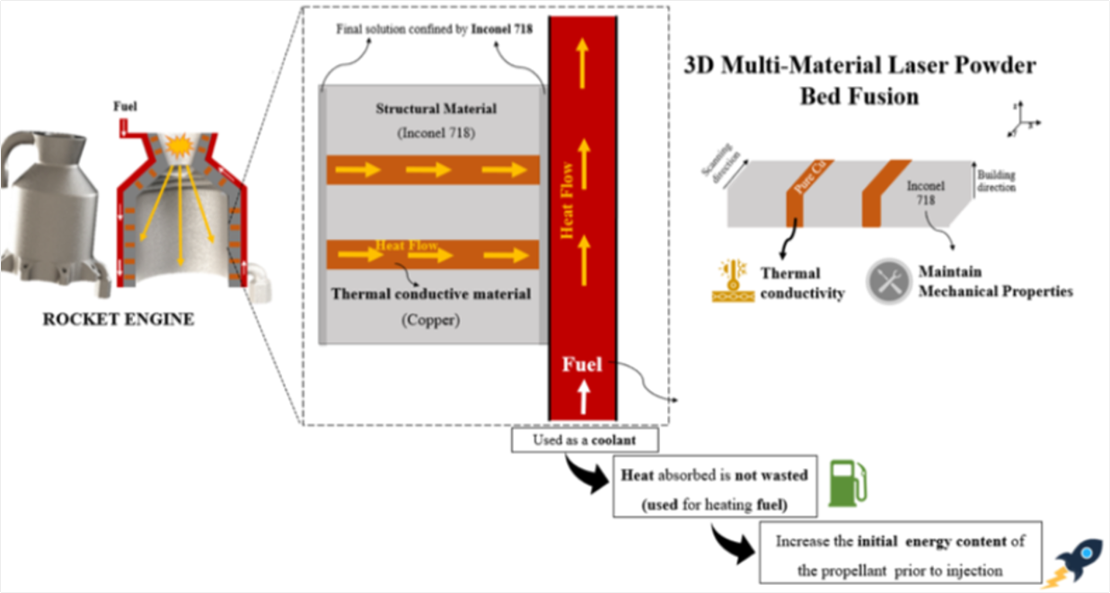

As product developers gain a deeper understanding of the potential offered by additive manufacturing and the design flexibility it provides, metal laser powder bed fusion (LPBF) has gained its position in a wide range of space applications. However, the current emphasis is mainly focused on mono and graded-material components. By incorporating multi-material components, it becomes feasible to leverage the specific advantages of different materials based on the requirements of each component. For instance, in heat exchange applications, it is possible to combine wear- and heat-resistant nickel alloys or steel with copper, which possesses excellent thermal conductivity.

This project is grounded on a disruptive approach: 3D voxel-based multi-material LPBF, the right material in the right place with an arbitrary 3D material layout, for obtaining site-specific properties. The focus is to explore the capabilities of LPBF to understand process-materials-property and controlling material interactions with a focus on Cu-based, Al-based, and Nickel-based alloys in the same component. The success of such multi-material complex components requires a thorough understanding of the metallurgical structures, intermetallic, residual stresses, chemical composition, phase transformation, and crystallographic phenomena/defects.

Together with University of Minho, we will (1) investigate the printability of multi-materials using the proposed approach and optimize the process parameters, (2) understand the relationship between the process parameters, the microstructure, mechanical, thermal, and surface properties of the resulting material therefore fundamental, and (3) develop a proof-of-concept laboratory prototype of the proposed multi-material component therefore implementation.