PROJECT AIM

• Identify the non-cohesive and cohesive regimes of granular systems;

• Develop DEM contact models for dry and cohesive systems, and calibration there of by laboratory experiments;

• Apply the adhesive contact model to describe industrial-scale tableting.

PROJECT DISCRIPTION

The work is at the closure stage in line with the objectives described above. We have achieved the first objective by conducting material characterization tests on limestone powders with a wide distribution of sizes, and thus cohesivity, with various shear testers. The results are currently being explored in more detail for the particle and continuum model calibrations of the second objective. For the third objective, we have conducted the high stress tableting study on the same limestone powders and the results will be published soon. In addition, an investigation of dilute to dense granular rheology has being conducted, culminating in the development of an extended generally valid model involving the dependence of density and macroscopic friction on dimensionless numbers that characterize shear rate, softness, friction, and cohesivity.

Figure 1. Schematic representation of the tableting process.

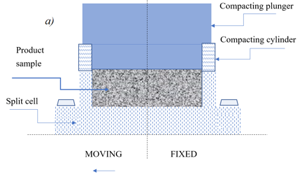

Figure 2. (a) Ajax Equipment full volume cell illustrated. (b) Eskal300 sample springing apart.