SEED is active in several research projects in the field of high temperature electrochemistry, ranging from CO2 Methanation to the design and degradation of a Metal Supported Solid Oxide Electrolysis (MS-SOEC).

For more information you can check out these pages

- CO2 Methanation

WHAT

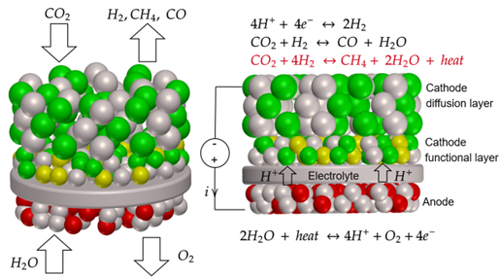

This project is about the development of new electrode materials and cell designs for synthetic methane production processes using proton-conducting ceramic electrolysers.

WHY

Nowadays, there is a global effort to find carbon-free alternatives to meet the worldwide energy and chemical feedstock demand. One of the more attractive alternatives is the production of green hydroagen and fuels derived from it. However, there are still several challenges for integrating green hydrogen technology with current industrial processes (e.g., Haber-Bosch, Sabatier or steam reforming reaction). In this landscape, intermediate temperature (400°C - 600°C) electrolysis becomes more attractive, mainly due to two reasons: The first one is related to their inherent higher efficiency compared to lower temperature approaches such as Proton exchange membrane electrolysis (PEM) or alkaline electrolysis. And the second one is the possibility of integration with thermochemical reactions, such as the methanation reaction, due to their operation temperature range. Consequently, the use of proton-conducting ceramic electrolyser cells (PCEC) is becoming more attractive, due to their temperature of operation window and the subsequent allowance to use a low-cost catalyst and simpler assembly design. This project investigates avenues to increase the competitiveness of this technology using both experimental and computational tools, with coke formation on the cell electrodes, low methane selectivity at high temperatures (> 400 °C) and the exothermic nature of the methanation reaction, being the main challenges to overcome.

HOW

The project comprises two distinct work packages. The first focuses on the experimental development of novel electrode catalysts and the subsequent evaluation of the cell performance. The second concentrates on the development of new numerical methods, encompassing the processing of experimental data and culminating in cell simulation to facilitate optimal cell design and operation.

FUND&COLAB

This is an ECCM Kickstart project funded by the Dutch Science Foundation (NWO) and co-funded by EIFER (European Institute for Energy Research) and Shell.

WHO

The experimental work is done by Dr. Suman and the numerical work is done by Dr. Julian Restrepo. The project is supervised by Dr. Aayan Banerjee.

- Design and Degradation MS-SOEC

WHAT

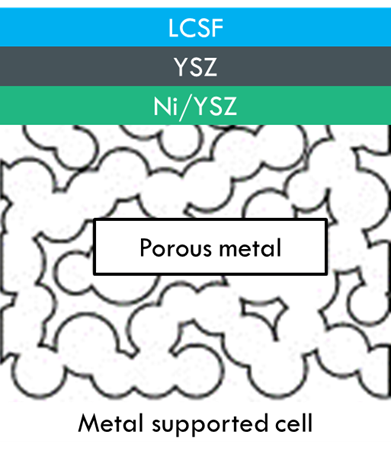

The project contains two parts. First is the design of a MS-SOEC. The cell design will be optimized in terms of layer thicknesses and microstructure. The cell design is then scaled up to a stack and eventually to a system. Second, the degradation of a (metal supported-) cell is investigated. The focus is on the migration of nickel in the fuel electrode during operation, i.e. Ni coarsening and depletion. The influence of different parameters like steam concentration, overpotentials, temperature and morphology will be investigated.

WHY

Compared to other types of electrolysers such as alkaline and PEM, solid oxide electrolysers are not yet at the same competitive level. The two things which hold the technology back are the heat demand during operation and the relatively high degradation rates. In this project, both of these shortcomings are addressed by developing a metal supported cell and investigating Ni migration. In a MS-SOEC, the functional layers are thinner than conventional solid oxide cells, which allows for operation at lower temperatures. Moreover, the high degradation rates are mostly attributed to the depletion of nickel near the electrolyte. The mechanism behind the movement of nickel is actively debated in the scientific community.

HOW

For the design and optimization of the MS-SOEC a 1-dimensional model is made of the membrane electrode assembly. After the optimization of the functional layers, the 1D model is connected to a channel model. The channel model will be validated with a to-be-built experimental setup. The setup will be able to test large planar cells and will be fitted with in situ gas composition analysis and segmented cell testing capabilities to observe gradients (temperature, current distribution, gas composition) across the cells. Ni migration will also be investigated experimentally using accelerated stress test protocols inside a button-cell test rig. The experiments will be used to verify existing hypothesis or develop a new one.

FUND&COLAB

The project is part of the NXTGEN HIGHTECH programme on the development of a new generation of electrolyzers to be made in the Netherlands. The NXTGEN HIGHTECH program is funded by the Nationaal Groeifonds of the Netherlands. Inside the project, we collaborate closely with TNO, HyGear, VSparticle, Spark-nano and Admatec.

WHO

The work for the project is done by Ir. Wisse Hersbach. He obtained his Bachelor and Master degrees at the University of Twente in Chemical Engineering. For his master thesis he worked on dense hydrogen separating membranes, specifically on the material Lanthanum Tungstate, which he finished Cum Laude. The work is done under supervision of Dr. Ing. A. Banerjee.